Tenmat FF102/50 Cavity Barriers and James Hardie Fire Resistant Cladding

James Hardie Cladding Products

James Hardie cladding and weatherboards are made from advanced fibre cement materials, which are non-combustible, compared to wood cladding and uPVC cladding. Because of its relatively high-density fibre cement is naturally resistant to adverse events such as fire, extreme weather conditions, pests, rot and fade.

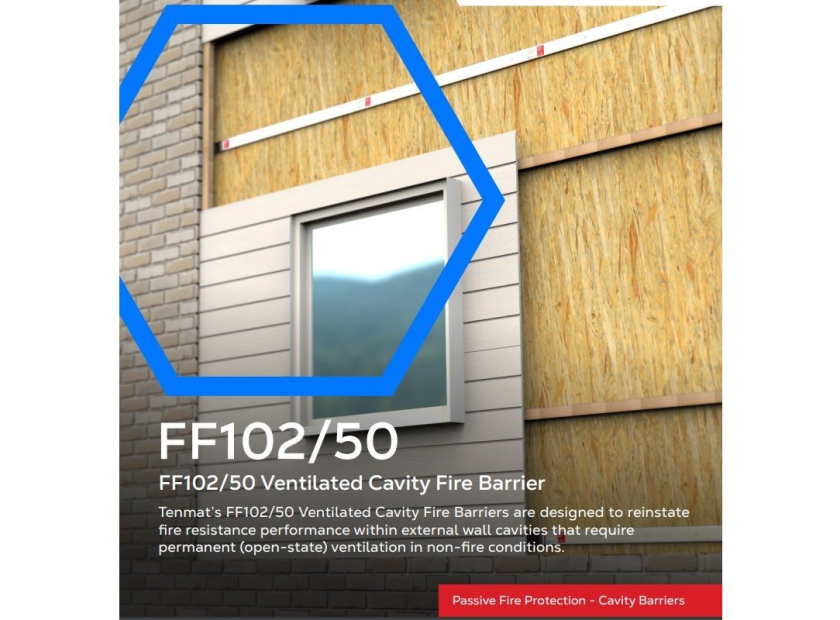

James hardie have partnered with Tenmat to design and promote the Tenmat FF102/50 which is a Ventilated Cavity FIre Barrier. lated Cavity Fire Barriers, are manufactured from a low smoke zero halogen high expansion intumescent material. They are designed to reinstate fire resisting performance to external wall cavities that are required to be ventilated (open-state) in non-fire conditions. The FF102/50 is manufactured from a rigid intumescent material allowing it to be provided in a strip format, it is also covered with a protective layer of aluminium foil for ease of handling. In the event of a fire the FF102/50 intumescent material will expand to close the external wall cavity, providing effective fire resistance, for integrity and insulation for up to 120 minutes depending upon the construction of the external walls.

The FF102/50 is designed for use within cavities of up to 50mm and once installed will close the remaining free air gap in front of the 6mm cavity barrier of up to a maximum of 44mm (depending on construction type). In case of a fire it is important that the walls of the house will protect you while your family seeks safety. Fire feasts on wood, and it melts vinyl, or uPVC, almost instantly. But James Hardie fibre cement cladding will not ignite when exposed to a direct flame, nor will it contribute fuel to a fire. James Hardie cladding, weatherboards and building facades are made from advanced fibre cement material, which is non-combustible, compared to wood cladding and uPVC cladding. With a high density and dimensional stability, fibre cement is naturally fire resistant.

All of the Hardie exterior products – Hardie® Plank (including Hardie VL) and Hardie® Panel cladding – perform extremely well in these tests, achieving the maximum fire protection rating for a coloured facade product. The fibre cement cladding would not contribute to the propagation of fire.

Latest Fire test report

Our fire test report has been updated! But what does this mean? Fire test reports can be difficult to understand, and therefore we thought we could it explain it for you.

Fire reports has to be done for all cladding products. And they have to comply with Building Regulations to gain Building Control approval in order to build in the UK.

Fire test reports test a number of criteria such as how a material reacts to fire, smoke production, heat transmission, flame spread, and emission of flaming particles. This in short, ensures that the building materials used in the overall construction is acceptable in case of fire.

James Hardie aims for the safest most fire-resistant cladding on the market. All of their fibre cement cladding products have the highest fire rating (A2 s1-d0) possible for a coloured exterior product, which means that they are non-combustible, see below.

What is a fire test report?

Fire reports have to be done for all cladding products. And they have to comply with Building Regulations to gain Building Control approval in order to build in the UK.

Fire test reports test a number of criteria such as how a material reacts to fire, smoke production, heat transmission, flame spread, and emission of flaming particles. This in short, ensures that the building materials used in the overall construction is acceptable in case of fire.

Who does the testing?

Testing companies accredited by United Kingdom Accreditation Service (UKAS) such as EXOVA, BRE Group, Effective and Chiltern Fire are able to test materials, products and systems to ensure compliance with fire test standards.

UKAS is a private, not for profit organisation and is appointed as the national accredited body to asses against internationally agreed standards, such as the ISO. They provide certification, testing and inspection services in different areas, one of them being fire testing and certifications.

What tests are conducted?

The tests conducted depend on the product and the use of the product, in this case Hardie® Plank weatherboard and Hardie® Panel cladding panels, which are used as exterior cladding products in residential housing and in commercial buildings such as schools and hospitals.

The tests are all ISO standardised test and classification is carried out in accordance with clause 10 of EN 13501-1:2002. The tests conducted are:

-

EN ISO 1182: tests, max temp rise, duration of flaming and mass loss

-

EN ISO 1716: how the top coat burns

-

EN 13823: single burning item test

The test results showed that Hardie® Plank and Hardie® Panel fibre cement weatherboards were compliant with all conducted tests and achieved the maximum fire protection rating for coloured facade products A2 s1-d0:

-

A2: reaction and behaviour to fire

-

s1: smoke production.

-

d0: classification in relation to flaming droplets/particles

The tests also shows that no flame-retardant additives were used in the production of Hardie’s fibre cement cladding products.

What does this mean for the customer?

James Hardie’s fibre cement cladding has the highest fire rating, it is designed to keep the whole family safe from fire in the home. The rating A2, means that the cladding is non-combustible and will not contribute to the spreading of fire. And since Hardie cladding will not ignite when exposed to direct flame or contribute fuel to a fire, it will not produce harmful smoke either.

Because the James Hardie cladding achieved the classification of A2 s1-d0 means that James Hardie cladding complies with all of the current building regulations for fire, regardless of building use, building height or boundary condition.

To view a copy of the Fire Test Report for James Hardie cladding products, click here.